Gasoline-max technology

Process

Synfuels China Gasoline-Max Technology selectively converts F-T heavy wax and light alkanes to gasoline product through fluidized-bed, fixed-bed, catalytic distillation and moving-bed. The process is described below:

• F-T heavy wax is hydrocracked to tertiary-olefins-rich gasoline and gas products on the surface of zeolitic catalyst in a FCC reactor;

• The tertiary olefins are etherified with methanol via catalytic distillation in a fixed-bed reactor to produce high octane ether compounds;

• Light straight-chain alkanes from F-T synthesis is catalytically reformed to aromatics in a moving-bed reactor, which can be used for the blending of gasoline products;

• FCC gasoline, etherified gasoline, and reformed gasoline components are blended to produce final clean gasoline product.

History

2012 Catalytic reforming of light straight-chain alkanes in a fixed bed reactor in laboratory; Fluid catalytic cracking of F-T wax in a fixed fluid-bed reactor using traditional FCC catalyst;

2013 Catalytic reforming of F-T short-straight-chain alkanes in a fixed bed reactor in laboratory; Scale-up of F-T heavy wax fluid catalytic hydrocracking process in a riser reactor using traditional FCC catalyst;

2014 Optimization of the catalyst for F-T short-straight-chain alkanes reforming; R&D on catalyst for hydrocracking of F-T wax;

Advantages

Synfuels China's Gasoline-Max Technology is designed for the production of 92 - 98# clean gasoline products, with the following advantages compared with traditional petroleum-based gasoline products:

• Nearly sulfur free in the final gasoline products

• Lower aromatics content

• Lower emission of pollutants and particulates

• Improved economic benefits

Diesel-max technology

The Diesel-Max Process Technology uses fixed-bed reactors for olefin polymerization, hydrotreating, hydrocracking, and hydroisomerization of F-T intermediate products. The technology has the following features:

• Hydrogenation process using non-sulfur catalyst

• Hydrocracking process using non-sulfur catalyst

• Heterogeneous coagulation depression process using non-noble metal catalyst

• Oligomerization process paired with C3-C9 olefin

• Suitable for the converting of F-T syncrudes (C3-C120 hydrocarbons)

• Proprietary catalyst technology for the upgrading of F-T syncrudes

History

2011 R&D on Diesel-Max Technology started

2013 Optimization of catalyst preparation, large-scale catalyst production

2014 Catalyst was used in Yitai CTL demonstration plant

2015 R&D on the second generation catalyst

Advantages

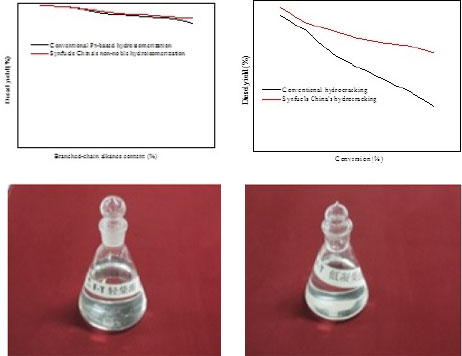

Synfuels China’s Diesel-Max Technology is designed for the production of 0#~-20# clean diesel product, with the following advantages:

- Sulfur-free in the product upgrading process

- High diesel yield from wax via hydrocracking process

- High activity for dimeric-hydrocarbons from light olefin via oligomerization process

- High branched-chain alkanes yield via non-noble hydroisomerization process

Heavy oil upgrading technology

Process

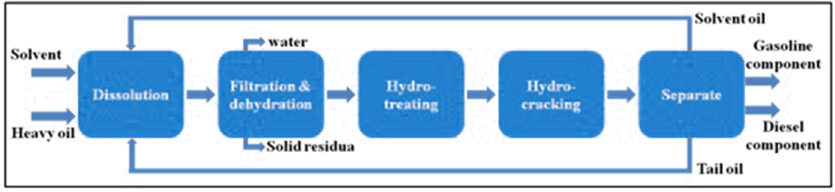

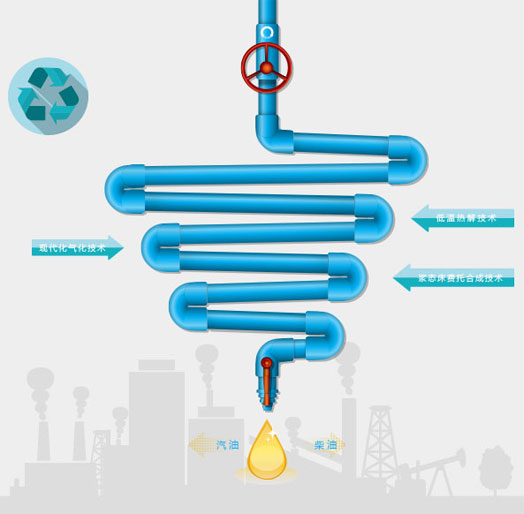

The Heavy Oil Upgrading Technology is mainly used for the production of gasoline and diesel blending components, including the following sections (Figure.1):

• Mixing of heavy oil and solvent oil

• Filtering of residues from the mixed oil, and centrifugal dehydration

• Pre-hydrotreating of filtered and dehydrated oil

• Hydro-cracking of the oil mixture

• Separation of gasoline/diesel distillates, solvent oil and tail oil

• Recycling of solvent oil and tail oil to the dissolution unit

Advantages

Synfuels China's Heavy Oil Upgrading Technology has the following advantages:

• Good feedstock adaptability

• No fractionation is required for the removal of tail oil from the feedstock

• High yield of gasoline and diesel components

• Solvent oil can be recycled

• Low energy consumption

Technical Support

Synfuels China provides the following technical support:

• R&D on solvent oil, catalyst and its optimization

• R&D on the process technology and its optimization

• Exploring low cost production scheme

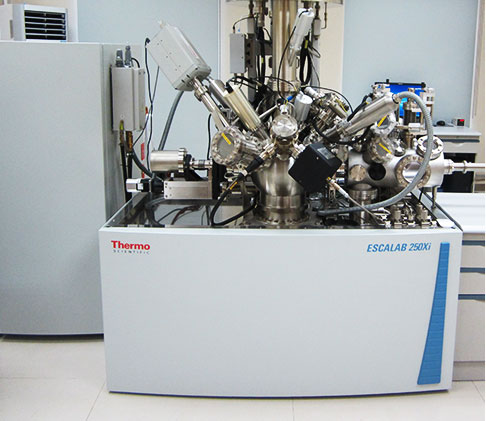

Due to the differences between indirect CTL products and traditional petroleum-based liquid fuels, Synfuels China has also carried out researches on the analysis of the composition of indirect CTL liquid fuels and wax, related performance tests, on-line monitoring and analysis of feedstock and process and products, to provide reliable operation data for the quality control of F-T production process. Meanwhile, Synfuels China has developed relevant analytical standards and test methods.

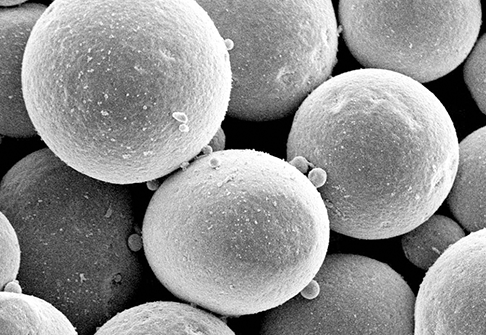

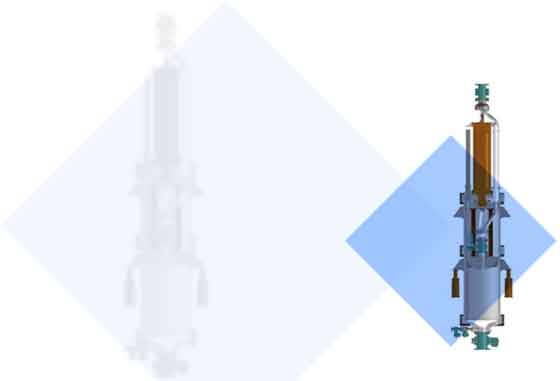

Synfuels China has developed its proprietary Medium Temperature Slurry-bed Fischer-Tropsch Process (MTSFTP) technology. It converts qualified syngas, which could be derived from coal, natural gas or biomass, into sulfur-free clean diesel products, with high diesel yield, low methane selectivity, and high thermal efficiency. Therefore, the MTSFTP technology improves the economic benefits of a CTL or GTL plant. Process:

Coal-based MTSFTP technology consists of three units - syngas production unit including coal gasification and syngas purification, Fischer-Tropsch synthesis unit which consists of Fischer-Tropsch synthesis and products separation, product upgrading where F-T syncrudes are upgraded into clean diesel, naphtha, and LPG. It has the following key features:

• High activity and stability of cheap iron-based F-T catalyst;

• The proprietary Medium Temperature Slurry-bed F-T Reactor greatly improves the thermal efficiency;

• The proprietary product upgrading technology produces high quality clean diesel product free of sulfur and nitrogen;

• All the processes are integrated and optimized to minimize the fixed investment on equipment.

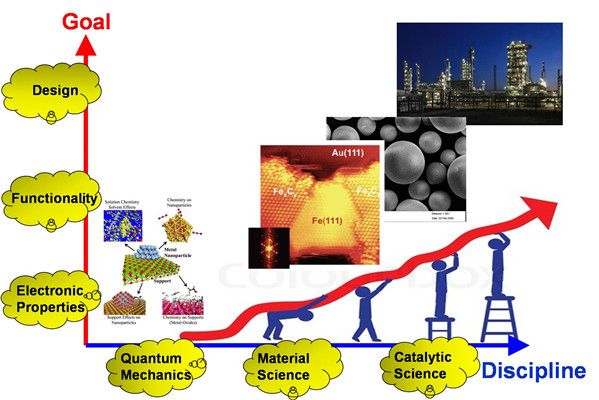

• Detailed studies have been carried out on every technical issue, and all key equipment are optimized on the basis of the first principles.

Research and development

• 1997-1999 Research on the hydrodynamics and kinetics of slurry-bed reactor F-T technology under the direction of Prof. Li Yongwang, research fellow of SXICC, CAS. SXICC II A-B catalyst was successfully developed.

• 2000-2004 Successful 15-20 bbl/d pilot test using the MTSFTP technology.

• 2005-2012 Three 4000 bbl/d demonstration CTL plants using MTSFTP technology were constructed in Inner Mongolia and Shanxi, and then operated at full load.

• 2013-present Three large-scale commercial CTL plants are under construction, and will be started up soon.

Technical advantages:

• The 30 bar by-product steam from F-T synthesis can be recovered due to the high operating temperature in the slurry-bed reactor, improving the total thermal efficiency of the whole plant.

• The oxygenates content, especially acid content in F-T syncrudes, is greatly reduced. This contributes to the high quality of diesel product, and reduces the fixed investment on equipment.

• The MTSFTP technology is flexible, and can be integrated in CTL, GTL, and BTL plants.

Hydrogenation of maleic anhydride

Technical development milestones:

• 1992-2001 Basic research on the hydrogenation of maleic anhydride (furfuraldehyde) and butanediol dehydrogenation in a fixed bed reactor.• 2002-2004 Integration and optimization of hydrogenation, dehydrogenation and coupling processes in fixed-bed reactor, and industrial demonstration.

• 2004-2014 Process optimization, engineering design, commercial application, and scale-up of catalyst production.

The low-pressure maleic anhydride hydrogenation technology has been promoted and applied in Inner Mongolia, Anhui, and other areas. The 5000 t/a γ- GBL unit in Inner Mongolia has achieved remarkable economic and social benefits. A new 10,000 t/a γ- GBL facility has been built in Anhui after further integration and optimization of the technology based on previous experience.

Furfuraldehyde hydrogenation technology

Imethyl oxalate hydrogenation

Technical development milestones:

• 2007-2011 Basic research on dimethyl oxalate ester hydrogenation in a fixed-bed reactor• 2012-2013 Integration and optimization of dimethyl oxalate ester hydrogenation in a fixed-bed reactor

• 2014-2015 Scale-up of catalyst production technology for dimethyl oxalate ester hydrogenation in a fixed-bed reactor

Based on research on hydration, dehydration and coupling reactions, high-quality catalyst has been developed based on the hydrogen spillover theory.

Fifteen patents in fine chemical engineering has been granted to Synfuels China, with more than 50 publications in top English journals. More than 20 PhD and master candidates have graduated with excellent results. Synfuels China has been awarded the second prize of National Technological Invention, and the first prize in technological invention of the Petrochemical Association, and the second prize of Shanxi Provincial Technology, etc.

During the multistage liquefaction process, feed coal (or heavy oil, or biomass) is first partially hydrogenated under moderate conditions to extract some light oil; the remaining semi-coke residue is then gasified to produce syngas. The syngas is converted to liquid fuels through Fischer-Tropsch synthesis. Steam at different levels from the gasification and Fischer-Tropsch synthesis units is used for the preheating and dehydration of coal (heavy oil, biomass and other raw material). The F-T liquid fuel is blended with light oil from the partial hydrogenation process to produce final diesel and gasoline products.

Technology research and development process

• 2008-2009 Construction of a 1 t/h pilot plant.

• 2010-2014 Pilot tests using brown coal, bituminous coal, coal tar, and heavy oil as feedstock.

Advantage:

• The operating conditions are much milder than those for direct liquefaction technology. This enables the steady operation of multistage liquefaction process.

• The oil products from the multistage liquefaction process can be easily refined, and used for the blending of final high quality gasoline and diesel products.

Various waste water is produced in coal chemical processes, such as gasification black-water, Fischer-Tropsch synthesis water, and wastewater from catalyst production, etc. The waste water needs to be treated effectively to meet the requirements of environmental protection and to improve the economic benefits of the plant by recovering useful products from the waste water. In addition to traditional distillation and oxidative degradation methods, Synfuels China has carried out R&D on new water treatment technologies such as freeze concentration method, hydrate method, and heat pump method.

Freeze Concentration Technology

Advantages:

• Treated water has high purity.

Hydrate technology

Advantages:

• Can be applied in many industries

• Treated water has high purity

MVR technology

Advantages:

• The equipment is easy to be manufactured.

• The process is controlled automatically.

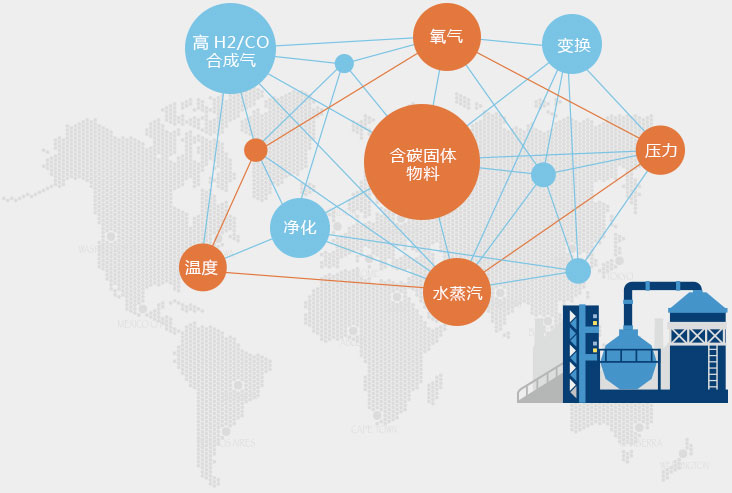

The gasification process is as follows. Carbonaceous solid powders are transported by a solid pump into the gasifier near its burner, where the powder is mixed with steam and oxygen to produce crude syngas under certain temperature and pressure. Ash in the coal drops downwards under gravity, and became slag in the slag sink in the gasifier. Melted ash is entrained by the high-temperature gas into the high-temperature and low temperature quench zones in the upper part of the gasifier, and solidified into solid dust. Portion of the solid dust drops down to the gasification zone below, and the remaining dust is carried out of the gasifier with syngas through the top outlet of gasifier. Quenched crude syngas is routed for further processing. The gasification technology has several features. The gasifier has a capacity of 4000 t/d. Solid pumps are used for the transportation of coal powder. In addition, water cooling walls are adopted, and burners are allocated on the side-wall, and internal quench zones are configured.

Technical advantages:

• High efficient solid pumps are used for the transportation of coal powder without carrying gas.

• High carbon conversion rate.

• High H2/CO ratio in the produced syngas.

• Optimized treatment of gasification waste water.

Published in 2017

Published in 2016

Published in 2015

Published in 2014

Published in 2013

Published in 2012

Published in 2011

Published in 2010

Published in 2009

Published in 2008

Published in 2007

Published in 2006

Published in 2005

Published in 2004

Published in 2003

Published in 2002

Published in 2001

Published in 2000

Published in 1999

Published in 1997