Relying on the innovation capability and engineering integration capability of Synfuels China Technology Co., Ltd., the company aims to improve catalyst technology and its production and sales on the basis of Synfuels China's proprietary CTL technology and related coal chemical industrial experience. Large-scale production of catalyst has been achieved, and the catalyst product is currently supplied to the three 160,000 t/a CTL demonstration plants (Inner Mongolia Yitai Group Co., Ltd., Shanxi Lu'an Mining Group Company, and Shenhua Group). The company will supply catalyst product and related technical support for future large-scale commercial CTL projects.

At present, there are more than 200 staff in the company, including 3 senior engineers, 19 engineers, and 44 associate engineers. Among them, bachelor degrees and postgraduate degrees (2 PhD, 22 masters, 56 bachelors) accounts for 82.7% of the staff. To meet the requirement of the company development, the allocation of human resources is continuously optimized to carry out cooperation between production, learning and research, forming an integrated technology development system for basic research, analysis, technology scale-up, catalyst production and sale. and the positive interaction between catalyst production and sales.

There are several departments in the company, such as R&D Department, Technology Department, Production Department, etc.

The R&D Department consists of three functional test centers: coal quality analysis and testing center, product analysis and testing center, and environmental monitoring center. There are 76 sets of equipment in the department, which is worth more than 50 million RMB. Over 70% of the equipment are latest international models or first-class equipment in China. The company obtained the CMA accreditation measurement certificate in November, 2011, and was qualified to carry out the relevant analytical testing and technical development.

The Technology Department is responsible for the operation of Yitai and Lu'an CTL demonstration plants as well as technical support work, plans and implements the "safe, steady, long-term, full-load and excellent" operation of the demonstration plants, designs and plans technical improvement, collects operational data and provides reliable engineering data, monitors the production and operation of equipments, optimizes processes and equipment, and maintains the long-term stable operation of the plant.

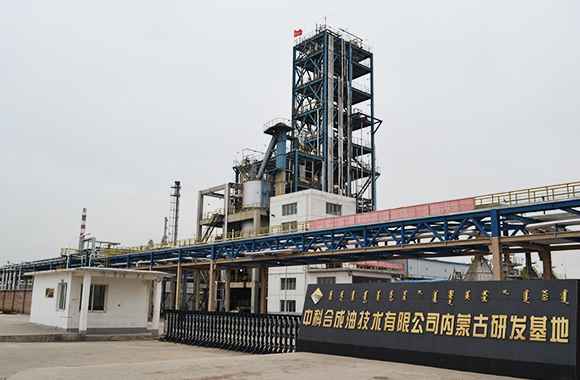

The Production Department is responsible for the enlargement of the high-tech laboratory techniques, ensures the start-up, operation, maintenance, technical improvements and construction guardianship of the pilot platform, collects data during operation of the testing project, describes and concludes the operational status in details, as well as provides commercialization device with the firsthand process operating parameters and operating procedures.

To meet the demand for catalyst of the first batch of million-ton commercial coal-to-liquids demonstration projects, the company started the construction of 48,000 t/a of coal liquefaction catalyst and industrial support for the project (the first phase of 0.12 million t/a) in 2013, and completed and put into stand-alone test at the end of 2014. The completion and implementation of this project has a very important strategic significance to enhance the technology industry support capability of Synfuels China Technology Co., Ltd. to improve local industrial level, to upgrade the industrial structure, to promote the sustainable and healthy development of coal chemical industry.