R&D on fixed-bed F-T catalyst and process technology

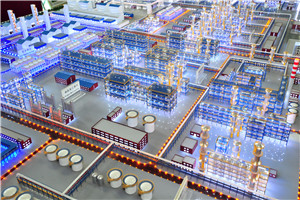

1980-1993Synfuels China Technology Co., Ltd (hereinafter referred to as "Synfuels China") proprietary CTL technologies includes series of catalyst technologies, product upgrading technologies and catalysts, F-T process technology and industrial software technology, process and product analysis standards, and relevant auxiliary technologies. Synfuels China owns the technology for the integration of low-temperature slurry-bed heavy distillates process and high-temperature light distillates process, and has systematically developed the simulation software for the simulation of all the processes in a CTL plant with relevant basic engineering process database from coal to the final oil products. As per the requirements of different clients, Synfuels China can carry out various activities, such as coal analysis, pre-planning, techno-economic analysis and product solutions, feasibility study at different scales using different feed coals, different gasifiers, different F-T catalysts, flexible product upgrading technology, and so on. Synfuels China prepares CTL process design packages with different capacity and related technical documents for its clients, providing effective guidance for the industrialization of the technology. So far, Synfuels China has applied 137 patents for its technologies, and has been granted 29 international patents and 91 invention patents in China. In addition, Synfuels China has developed three national standards of CTL technology and has more than 510 publications. Synfuels China also has a copyright for CTL technology design software.

There are many high-quality and experienced technical experts in Synfuels China in R&D on processes and engineering, and design engineers. They provide technical support and consulting services on equipment design, construction, and commissioning.

The proper training of technical personnel and operators plays an important role for the smooth commissioning and steady operation in a CTL plant. Synfuels China provides training services in pilot plants and laboratory for technicians and operators to improve their theory, safety, and operation skills to ensure the safe , steady and efficient operation in a CTL plant.

As the main provider of engineering services, SFC Engineering Company focuses on the engineering problems to solve the engineering and technical issues during the industrialization of indirect coal-to-liquids technology, and has formed a seamless industrial-support system from scientific research - technology - engineering design - EPC services, in order to transform scientific and technological achievements into productivity and enhance the engineering development ability for large-scale coal-to-liquids facilities by utilizing centralized engineering resources.

SFC Engineering Company actively participates in R&D on technology scale-up with unique ideas and understanding of the commercialization of a new technology, has the secondary R&D capability on process and special equipment. This seamless connection with technology research ensures the smooth industrialization of new technologies, providing excellent technological support and services in the industry.

SFC Engineering Company has obtained several qualification certificates, including Class A of engineering design qualification in the chemical, petrochemical and pharmaceutical industry (Chemical Engineering), qualification of contracting foreign projects, Class B of engineering consultation in chemical industry, and design qualification of pressure vessel and pressure pipeline, as well as certificates for engineering design, project consulting, EPC, and project management.

As a leading company in R&D on engineering in indirect coal-to-liquids industry in China, SFC Engineering Company owns several patents proprietary technologies, and provides various services, such as engineering consultation, development of process design package, engineering design, R&D and supply of internal parts for F-T reactor and catalyst reduction reactor, project management, and EPC services. There are more than 460 employees, including over 350 engineering designers and 60 project management staff.

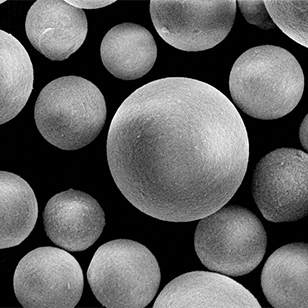

Fischer-Tropsch synthesis catalyst

Synfuels China carries out various research on F-T synthesis catalyst, including the preparation of chemical catalysts, catalytic reaction engineering, catalyst preparation, catalyst design and optimization theory, the relationship between catalyst microstructure and performance, the detailed analysis on the stability and activity as well as the selectivity of catalyst, catalytic reaction kinetics and mechanisms, development of new catalyst system, and catalytic materials etc. Currently, series of F-T catalysts has been redesigned and developed.

Synfuels China has successfully developed the low-temperature slurry-bed Fischer-tropsch synthesis process and proprietary high-temperature slurry-bed Fischer-tropsch synthesis process technology. A 1500 t/a F-T catalyst facility has been constructed by Ssynfuels China Huainan Catalyst Co., Ltd. , and produced qualified catalyst product, which has been supplied and used in the 160,000 t/a CTL demonstration plants owned by Yitai Group in Inner Mongolia and Luan Group in Shanxi. In addition, a 12,000 t/a F-T catalyst factory has been build to supply the catalyst required by large-scale commercial CTL plants with a capacity of millions t/a in the near future.

-

1980-1993

-

1997-1999

R&D on slurry-bed F-T catalyst and process technology

1997-1999 -

1999-2000

Breakthrough on slurry-bed Fe-based catalyst in laboratory

1999-2000 -

In 2001

Construction of 1000 t a slurry-bed pilot plant started

In 2001 -

2002-2008

Commissioning of pilot plant

2002-2008 -

In 2004

Successful R&D on low-temperature slurry-bed Fe-based catalyst

In 2004

-

In 2008

Successful R&D on high-temperature slurry-bed Fe-based catalyst 1500 t a F-T catalyst facility constructed and put into operation

In 2008 -

In 2009

Successful commissioning of 160,000 t a CTL demonstration plant, using high temperature slurry-bed Fe-based catalyst and process technology

In 2009 -

In 2010

The CTL demonstration plant was operated at full-load, where all operation parameters reached or exceeded advanced international levels

In 2010 -

In 2014

12,000 t a F-T catalyst factory was build

In 2014

Technical advantages

After many years' work on technology and scale-up of production, Synfuels China technical team has accumulated rich experiences R&D, production and usage of catalysts, developed a set of patent technologies on catalyst loading, catalyst reduction and application, and has the capacity to provide technical supports for the construction and commissioning of a CTL plan and its operation.

Yitai CTL Demonstration Project

During the planning, design and construction of this project, the technical scheme is optimized to minimize project investment. Meanwhile, advanced technologies and processes are adopted for energy-saving, water-saving and environment protection, and all waste water is recycled and achieved zero discharge.

Using our own proprietary indirect coal-to-liquids technology in China, this project realized its industrialization of the technology, and filled the domestic gap in the CTL industry. Yitai Group played an important role in the research and development, and industrialization process, and made contribution to the implementation of national CTL energy strategy. The project has significant importance for the industrialization of China's proprietary CTL technology and national energy security. It provides a new direction for coal industry, especially local coal mining companies, and will promote the social and economic development in local communities.

Lu'an CTL Demonstration Project

On 7 July 2009, catalyst was first loaded into the Fischer-Tropsch synthesis slurry-bed reactor, and produced high-quality liquid fuels after more than 70 hours commissioning. The successful start-up f this project demonstrated that Synfuels China's F-T catalyst, F-T reactor and process were at the leading position in international CTL industry.

The successful operation of this project has significant importance for the restructuring of industries, change of economic growth mode, diversifying of energy structure. It promotes the implementation of national energy strategy, and accelerating the transformation of Shanxi Province from coal production to coal chemical industry and the construction of new energy and industrial base.

Shenhua CTL Demonstration project

Shenhua Ningmei 4 mt/a CTL Project

The project uses coal as feedstock, and converts 20.36 mt/a coal to produce 4.052 mt/a liquid fuels, including 2.733 mt/a diesel for blending, 983,000 t/a naphtha, 336,000 t/a LPG, 128,000 t/a by-product sulfur, 75,000 t/a by-product mixed alcohols, and 107,000 t/a by-product ammonium sulfate.

As the core technology provider, Synfuels China provides the technology licensing and process design package for F-T synthesis unit and product upgrading unit. Synfuels China Engineering Company is responsible for the plot plan, basic engineering design, detailed engineering design and procurement services for F-T synthesis unit, product upgrading unit, deaerated water and condensates treatment station, and intermediate liquid tank farm.

This project is currently under construction, and is scheduled to be commissioned in August 2016.

Lu'an Integrated CTL Project

As the General Design Institute for this project, Synfuels China provides the process design package for F-T synthesis unit and product upgrading unit; and EPC services for F-T synthesis unit, product upgrading unit, intermediate tank farm; and engineering design for purification unit, process and heating pipelines, power supply & distribution system, and central control room. This project is under construction, and is scheduled to be commissioned by the end of 2017.

Yitai 1.2 mt/a Fine Chemical Project

This project is under construction, and is scheduled to be commissioned by the middle of 2017.